Seating Matters Kanban Tour: Total Ownership and Visual Control

This well-developed Kanban system ensures materials arrive on time, prevents stockouts, and allows anyone, even visitors, to understand inventory status at a glance.

This well-developed Kanban system ensures materials arrive on time, prevents stockouts, and allows anyone, even visitors, to understand inventory status at a glance.

From hotel-quality coffee machines to dual dishwashers to perfectly centered cups with placement guides – when leadership cares about these details, employees care about product quality.

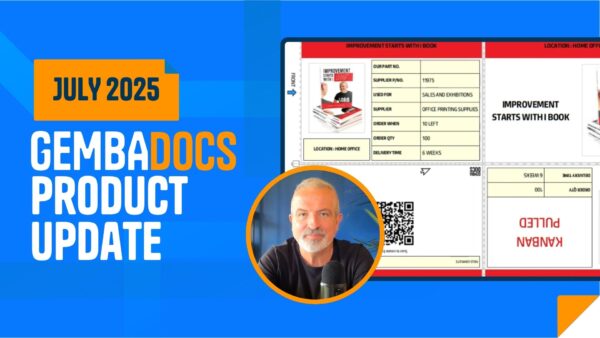

From multilingual documents to customizable cards, skills tracking, and analytics upgrades, these changes are built to simplify work for teams on the shop floor and in the office.

From eliminating purchasing departments to empowering new hires to create SOPs on day one, discover the digital tools revolutionizing American manufacturing workflow management.

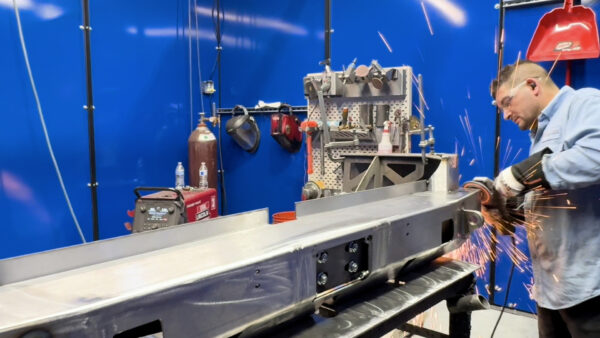

Tour Seating Matters’ world-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

We introduce Kanban email automation, SOP draft capabilities, mobile UI improvements, and QR code changes. Plus French language support now available.

Rototherm’s Lean Tour series brings together eight focused sessions on practical, operator-led improvements, visual management, and digital enablers—each designed to show how a wholehearted, hands-on approach drives tangible results on the shop floor.

Discover how British Rototherm embeds Lean from the moment you walk in: safety point-of-use, brilliant visual controls, daily routines, “house rules”, and even AI agents acting as employees.

In this Q&A, Brian shares the exact strategies they used to engage frontline workers, simplify documentation, and scale SOPs across every department.

We’ve added step-by-step timings, bulk SOP uploads, Kanban upgrades, mobile […. open to discover it all]