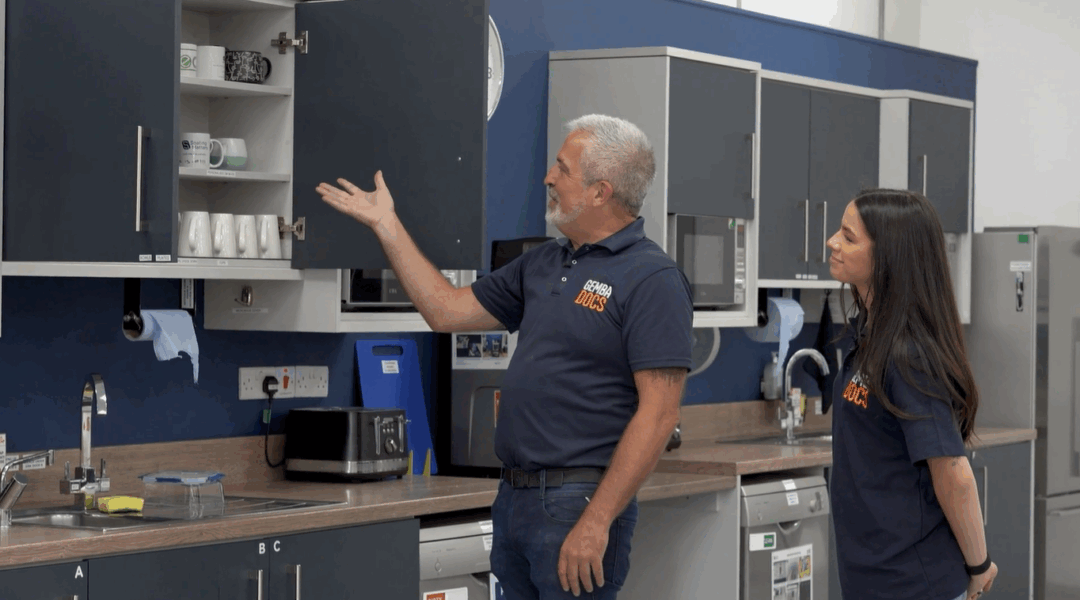

Our recent tour of Seating Matters canteen, with Tom and Alisha, demonstrates how lean principles extend beyond the production floor.

With no dedicated cleaners, every employee takes ownership of maintaining the space using a rota system documented in GembaDocs. From the high-end coffee machine and dual dishwashers with clean/dirty indicators to perfectly organized cupboards with centered cups and helpful placement guides, every detail reflects the company’s commitment to visual management and respect for people.

At 4:30 PM on a Thursday, the space is spotless – not because of policing, but because of culture.

Tour Breakdown

Tom opens with the principle that “lean starts in the kitchen and lean starts in the bathroom” – if these shared spaces are well-maintained, it reflects the broader organizational culture.

No Dedicated Cleaners - Total Ownership

- Self-cleaning system: No professional cleaners employed at Seating Matters

- Everyone cleans: All employees are responsible for maintaining both the kitchen and their own work products

- Rota system: Everyone has a designated time when they need to clean

- GembaDocs for cleaning schedules: Documentation shows how often tasks need to be done and who’s responsible

- Result: The kitchen always looks immaculate

Break Room Amenities: Respect for People

Pool Table and Darts

- Not just decorative – actively used by employees

- Tom and others were playing earlier during the visit

- Creates a genuine break space, not just a functional room

Premium Coffee Setup

- Not “any old crappy coffee machine and a kettle”

- High-level café or hotel-quality espresso machine

- Hot water dispenser with clear hot/cold indicators

- Instant access, so no waiting for kettles to boil

- Shows investment in employee experience

- GembaDocs even on the coffee machine for instructions

Dual Dishwashers

- Two dishwashers available (Tom notes this is “one of my ambitions in life”)

- Clear dirty/clean markers on each

- No need to open doors to check status

- Visual management extends to appliances

- GembaDocs positioned in front of dishwashers

Visual Management in the Cupboards

- Many lean practitioners dislike cupboard doors because “doors tell lies” – at Seating Matters, the doors don’t lie! What’s inside is exactly what you’d expect

- Cupboard management: cups perfectly centered on shelves, not randomly placed

Standardized placement maintained - Even includes a GembaDocs mug (owner clearly has taste!)

Thursday Afternoon Reality Check

The 4:30 PM Test…

- Tour conducted late Thursday afternoon (4:30 PM)

- Not prepared for visitors -“this is just how it is”

- Kitchen is “cleaner than a whistle, cleaner than most people are at home”

- Nobody acting as a “policeman” to enforce cleanliness

- No supervision needed

- High-level maintenance happens naturally

- Result of culture, not compliance

Small Details, Big Impact

Throughout the tour, Tom emphasizes “all these little details that I love”:

- Quality equipment showing respect for employees

- Visual indicators (hot/cold, clean/dirty)

- Standardization even in break spaces

- GembaDocs integrated everywhere, even in social areas

- Everything has its place and stays in its place

- Everything has a visual cue to what is what, even the cutlery holders

Takeaways

Key Takeaways for Manufacturing Leaders:

- Lean culture is proven in shared spaces, not just production areas – The canteen test reveals true organizational culture. At 4:30 PM on a Thursday with no cleaners and no supervision, the Seating Matters kitchen is spotless. When lean principles work in the break room, they’re genuinely embedded in how people think, not just what management mandates on the factory floor.

- Respect for people means investing in their experience – The hotel-quality coffee machine, dual dishwashers, pool table, and darts aren’t frivolous expenses… they’re statements about employee value. When you provide premium equipment and genuine break facilities, you communicate that people matter beyond their productivity, which reinforces the cultural foundation that makes systems like total ownership actually work.

- Visual management eliminates mental burden everywhere – From clean/dirty dishwasher indicators to hot/cold water labels to cup placement guides in cupboards, visual controls remove the need to think, remember, or guess. This isn’t just efficiency, it’s cognitive relief that allows people to focus their mental energy on things that matter rather than basic navigation and decision-making, even in spaces meant for relaxation.